Ts'ebetsong ea letsatsi le letsatsi ea tlhahiso, sekepe sa khatello ke mofuta oa sekepe se koetsoeng se ka mamellang khatello.E bapala karolo ea bohlokoa mafapheng a mangata a kang indasteri, sechaba le sesole, hammoho le mafapheng a mangata a lipatlisiso tsa saense.Lijana tsa khatello li sebelisoa haholo indastering ea lik'hemik'hale le indastering ea petrochemical, haholo-holo bakeng sa ho fetisa mocheso, ho fetisa boima, ho itšoara le mekhoa e meng ea theknoloji, hammoho le ho boloka le ho tsamaisa khase tlas'a khatello kapa khase e nang le metsi.

Welding ke ts'ebetso ea bohlokoa ea tlhahiso ea likepe tsa khatello.Ho ea ka phapang ea thepa, kereiti, sebopeho sa lik'hemik'hale le ts'ebetso ea welding, ts'ebetso ea welding e kenyelletsa welding ea arc, welding e ka tlas'a metsi, welding ea tungsten argon arc, welding ea MIG joalo-joalo.Joalo ka sebopeho se tloaelehileng sa tjheseletsa, li-welds tse amehang ho tjheseletsa sekepe sa khatello hangata ke li-curve tsa sebaka se rarahaneng, 'me ho na le litlhoko tse phahameng tsa ho cheselletsa ts'ebetsong ea tlhahiso.Ho ntlafatsa boleng ba tjheseletsa le boemo ba boiketsetso ba mochini ho bohlokoa haholo ho sekepe sa khatello esita le indastering eohle ea li-welding.

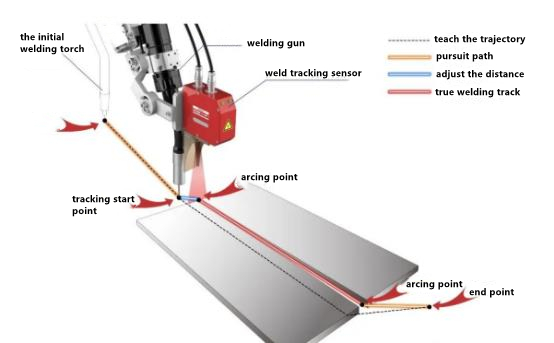

Ka nts'etsopele e potlakileng ea lisebelisoa tsa othomathike, theknoloji ea welding ea mochini oa khatello e ntse e hola.liroboto Industrial a hlomelloa le laser tjheseletsa seam latedisa tsamaiso le bolelele le lateral jarolla ka ho iketsa, 'me joale hlokomela jarolla ka ho iketsa seam,' me e se e le mokhoa o ka sehloohong, ka rarolla ho nepahala ha workpiece e tlang lintho tse bonahalang, tooling ho nepahala ke likhato tse fapaneng tsa phoso.Fokotsa haholo mosebetsi oa ho ruta oa liroboto tsa inthaneteng.

Shanghai JieSheng roboto e ikemetseng e kopantsoeng le laser welding visual weld seam tracking system, e ka tataisa roboto ea nako ea nnete ea phetoho ea weld kapa mochini oa welding, tokiso ea othomathiki ea mohala oa welding, lihlahisoa tsa ho nepahala ho phahameng, ts'ebetso e tsitsitseng, lebelo la karabelo, e sebelisoang haholo linthong tse fapaneng. joalo ka tšepe ea k'habone, tšepe e sa hloekang, aluminium alloy khatello ea seketsoana, leano le holileng la tekheniki, Ts'ehetso ea TIG, MAG, MIG, welding ea arc e kenelletseng, welding ea laser le mekhoa e meng ea tlhahiso.

Nako ea poso: Nov-09-2022