Haufinyane tjena, motsoalle oa bareki oa JSR o ile a etsa projeke ea tanka ea khatello ea liroboto. Lisebelisoa tsa moreki li na le litlhaloso tse fapaneng 'me ho na le likarolo tse ngata tse lokelang ho chesetsoa. Ha ho etsoa tharollo e ikemetseng e kopantsoeng, hoa hlokahala ho netefatsa hore na moreki o etsa welding ea sequential kapa welding spot ebe o sebelisa roboto ka botlalo. Ho etsoa. Nakong ena, ke ile ka fumana hore o ne a e-na le lipelaelo mabapi le khetho ea boemo, kahoo JSR e ile ea e tsebisa bohle ka bokhutšoanyane.

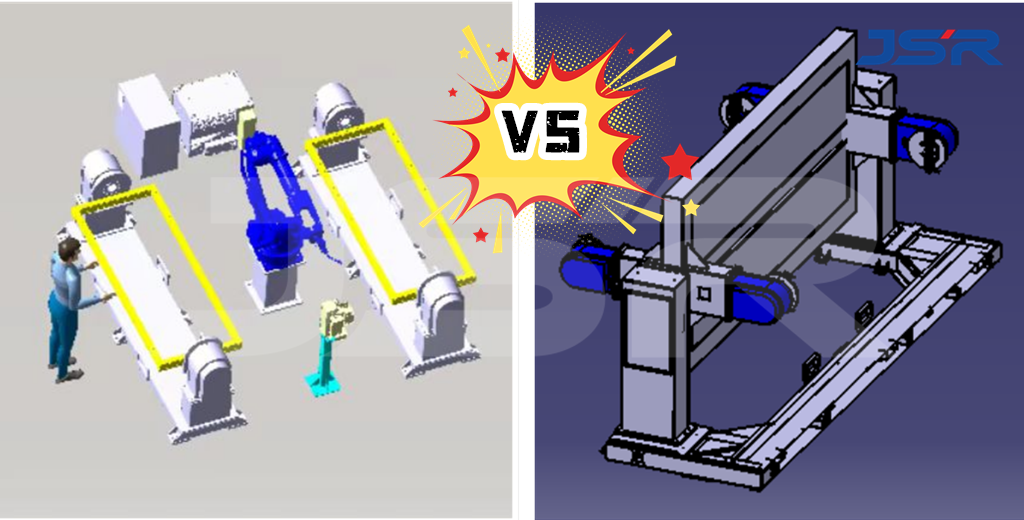

Li-Dual-Station-Single-axis Headstock le Tailstock Vertical Flip Positioner

VS Three-axis Vertical Flip Positioner

Setsing sa ho tjheseletsa liroboto, li-dual-station Single-axis headstock le tailstock vertical flip positioner le tse tharo tse otlolohileng tsa flip positioner ke lisebelisoa tse peli tse tloaelehileng tsa ho beha maemo, 'me li na le melemo ea tsona maemong a fapaneng a ts'ebeliso.

Tse latelang ke maemo a ts'ebeliso ea bona le lipapiso:

Sebaka sa liteishene tse peli tsa axis ea hlooho le mohatla:

E loketse bakeng sa maemo ao ho ona workpiece e hlokang ho potoloha le ho behoa nakong ea ts'ebetso ea welding. Ka mohlala, moleng oa tlhahiso ea tjheseletsa ea 'mele oa koloi, li-workpieces tse peli li ka kenngoa liteisheneng tse peli ka nako e le' ngoe, 'me ho potoloha le ho behoa ha li-workpieces ho ka finyelloa ka hlooho e le' ngoe le tailstock positioner, kahoo ho ntlafatsa katleho ea tlhahiso.

https://youtube.com/shorts/JPn-iKsRvj0

Setulo se otlolohileng sa li-axis tse tharo:

E nepahetse bakeng sa maemo a rarahaneng a ho tjheseletsa a hlokang ho potoloha le ho phethola mesebetsi ka nqa tse ngata. Ka mohlala, indastering ea sepakapaka, ho hlokahala ho cheselletsa li-fuselage tse rarahaneng tsa lifofane. Sebopeho sa li-axis tse tharo tse otlolohileng se khona ho bona ho potoloha ha li-axis tse ngata le ho bilika ha sesebedisoa ka nqa tse rapameng le tse theohileng ho fihlela litlhoko tsa ho tjheseletsa ka likhutlo tse fapaneng.

https://youtu.be/v065VoPALf8

Molemo oa ho bapisa:

Sebaka sa liteishene tse peli tsa axis ea hlooho le mohatla:

- Sebopeho se bonolo, se bonolo ho sebetsa le ho se hlokomela.

- Lisebelisoa tse peli tsa mosebetsi li ka sebetsoa ka nako e le 'ngoe ho ntlafatsa katleho ea tlhahiso.

- E loketse mesebetsi e meng e bonolo ea welding, joalo ka lisebelisoa tsa mosebetsi tse hlokang axis e le 'ngoe ea ho potoloha.

- Theko e tlase ho feta ea li-axis tse tharo tse otlolohileng.

- Welding e fapoha pakeng tsa liteishene tse ka ho le letšehali le tse nepahetseng. Ha ba tjheseletsa seteisheneng se seng, basebetsi ba lokela ho kenya le ho laolla thepa ka lehlakoreng le leng.

Setulo se otlolohileng sa li-axis tse tharo:

- E khona ho lemoha ho potoloha le ho phuphusela ha li-multi-axis 'me e loketse mesebetsi e rarahaneng ea ho cheselletsa.

- Nakong ea welding ea liroboto, basebetsi ba hloka feela ho tlatsa le ho laolla lisebelisoa tsa mosebetsi ka lehlakoreng le le leng.

- E fana ka maemo a feto-fetohang le ho nepahala, e ka finyellang litlhoko tsa li-angles tse sa tšoaneng tsa tjheseletsa.

- E loketse li-workpieces tse nang le boleng bo phahameng ba welding le litlhoko tse nepahetseng.

Ho akaretsa, ho khetha sebaka se loketseng ho ipapisitse le litlhoko tse ikhethang tsa mosebetsi oa welding, ho kenyelletsa le lintlha tse kang ho rarahana ha workpiece, angle welding, katleho ea tlhahiso le litlhoko tsa boleng ba welding.

Nako ea poso: Feb-20-2024