1. Sekaseka le ho rera litlhoko:Khetha mofuta o nepahetseng oa liroboto le tlhophiso ho latela litlhoko tsa tlhahiso le litlhaloso tsa sehlahisoa.

2. Ho reka le ho kenya: Reka lisebelisoa tsa roboto ebe u li kenya moleng oa tlhahiso. Ts'ebetso ena e kanna ea kenyelletsa ho lokisa mochini ho fihlela litlhoko tse ikhethileng tsa welding. Haeba ho le thata ho e kopanya, ikopanye le JSR, 'me moenjiniere o tla u etsetsa tharollo ho latela litlhoko tsa hau.

3. Mananeo le debugging: Litsebi tsa litsebi li hlophisa roboto ho etsa mesebetsi e itseng le ho e lokisa ho netefatsa hore roboto e khona ho etsa mosebetsi ka nepo.

4. Ts'ebetso le tlhokomelo: Ka tlhahiso ea letsatsi le letsatsi, roboto e sebetsa ho latela lenaneo le reriloeng esale pele.

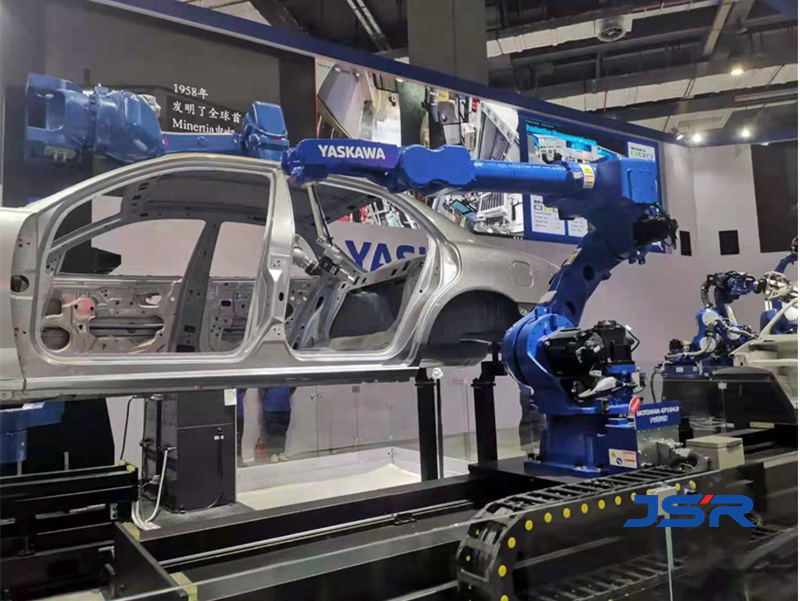

Melemo ea Liroboto tsa Indasteri ho Welding Automotive Automation Manufacturing

Tšireletseho e ntlafetseng:Ho cheselletsa liroboto ho fokotsa ho pepeseha ha basebetsi tikolohong e kotsi, ho kenyeletsoa mosi o chefo, mocheso le lerata.

Litšenyehelo:Liroboto ha li hloke ho phomola 'me li ka sebetsa bosiu le motšehare, li fokotsa litšenyehelo tsa basebetsi le lisebelisoa ka lebaka la phoso ea batho. Ho sa tsotellehe letsete le phahameng la pele, liroboto li fana ka phaello e phahameng ea lichelete ka ho eketsa katleho ea tlhahiso le ho fokotsa litekanyetso tsa lisebelisoa.

Ho sebetsa hantle le ho nepahala:Liroboto li ka lula li hlahisa likarolo tse cheselitsoeng tsa boleng bo holimo tse fihlelang maemo a thata a indasteri mme li ka etsa mesebetsi e rarahaneng joalo ka ho cheselletsa, ho fafatsa le ho phekola holimo.

Mefuta-futa:Liroboto li ka hlahisoa ho etsa mesebetsi e fapaneng, e lumellang phetoho e potlakileng ea lits'ebetso tsa tlhahiso ha ho hlokahala.

Nako ea poso: Jul-30-2024