Lintlha tse Amang ho Finyelleha ha Liroboto tsa Welding

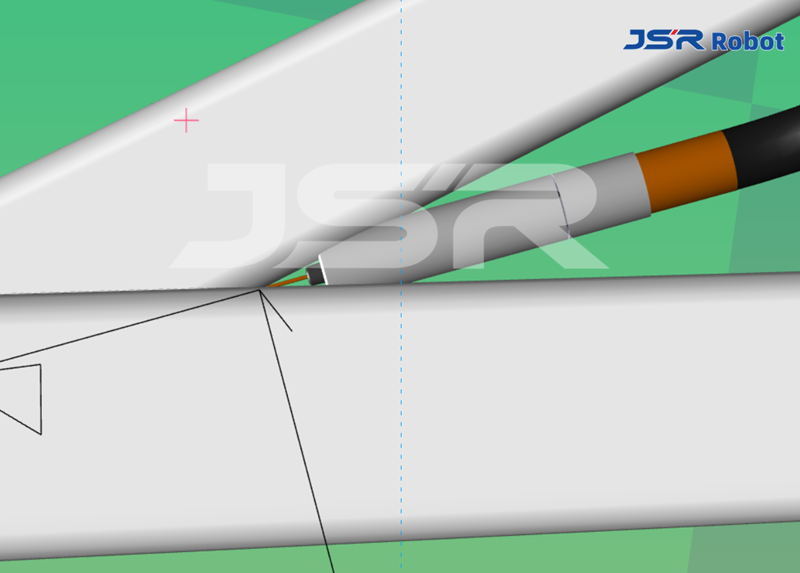

Haufinyane tjena, moreki oa JSR o ne a sa tsebe hantle hore na sesebelisoa se ka chesetsoa ke roboto. Ka tlhahlobo ea baenjiniere ba rona, ho ile ha tiisoa hore angle ea workpiece e ke ke ea kenngoa ke roboto le hore angle e lokela ho fetoloa.

Liroboto tse chesellang ha li khone ho fihla mahlakoreng 'ohle. Lintlha tse ling tse susumetsang ke tsena:

- Mekhahlelo ea Tokoloho: Liroboto tsa welding hangata li na le likhato tse 6 tsa tokoloho, empa ka linako tse ling sena ha sea lekana ho fihlela li-angles tsohle, haholo-holo libakeng tse rarahaneng kapa tse koaletsoeng.

- Qetellong-Effect: Boholo le sebōpeho sa toche ea welding e ka fokotsa mefuta ea eona ea ho tsamaea libakeng tse moqotetsane.

- Tikoloho ea Mosebetsi: Litšitiso tse tikolohong ea mosebetsi li ka sitisa motsamao oa roboto, tsa ama li-angles tsa eona tsa welding.

- Thero ea Tsela: Tsela ea motsamao oa roboto e hloka ho reroa ho qoba likhohlano le ho netefatsa boleng ba welding. Ho ka 'na ha e-ba thata ho finyella litsela tse ling tse rarahaneng.

- Moqapi oa Workpiece: Geometry le boholo ba mosebetsi oa matsoho li ama tsela eo roboto e fumanehang ka eona. Li-geometri tse rarahaneng li ka hloka maemo a khethehileng a tjheseletsa kapa litokiso tse ngata.

Lintlha tsena li ama ts'ebetso le boleng ba liroboto tsa welding mme li tlameha ho nahanoa nakong ea moralo oa mosebetsi le khetho ea lisebelisoa.

Haeba metsoalle efe kapa efe ea bareki e sa tiisehe, ka kopo ikopanye le JSR. Re na le lienjineri tse nang le boiphihlelo le tse hloahloa ho u fa litlhahiso.

Nako ea poso: May-28-2024