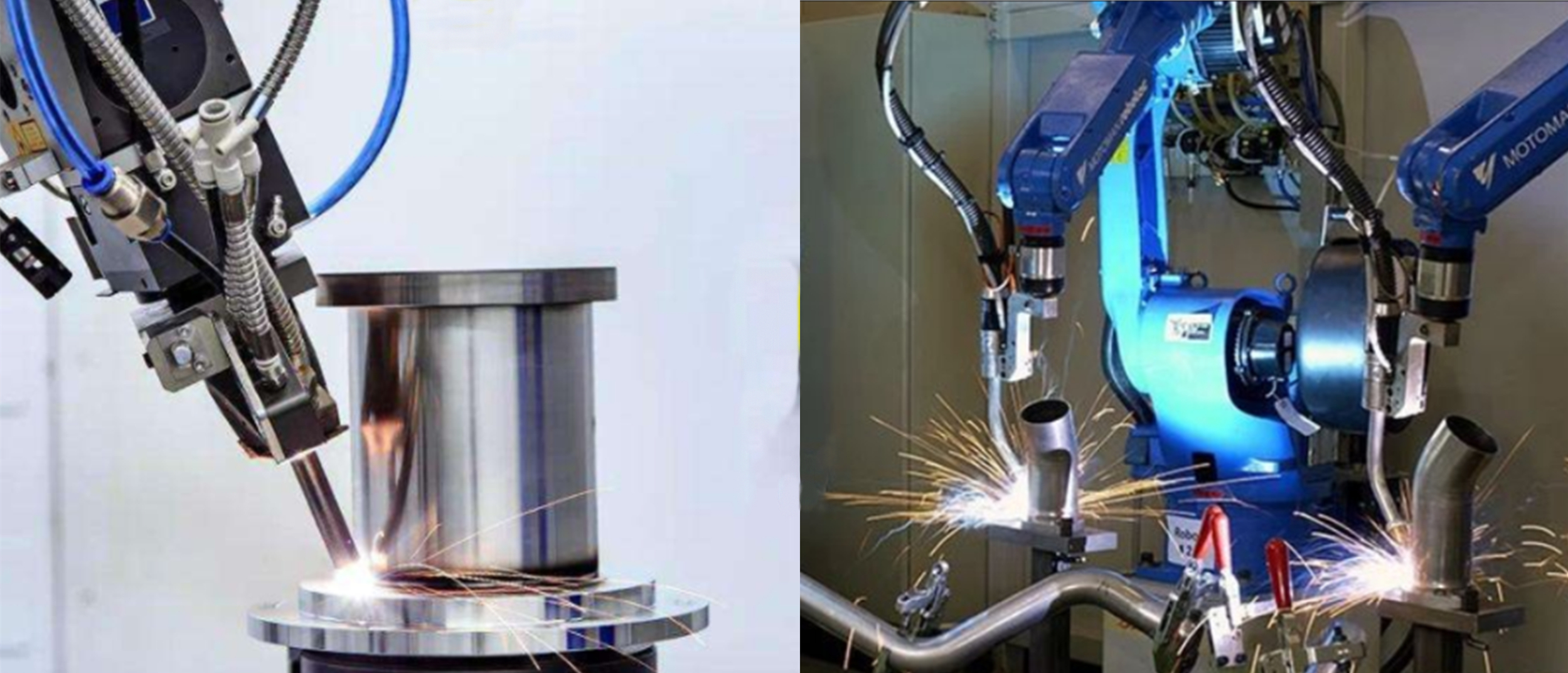

Roboto laser tjheseletsa tsamaiso e entsoe ka tjheseletsa roboto, terata fepa ka, terata fepa ka lebokose la mochine, tanka ea metsi, laser emitter, laser hlooho, ka ho tenyetseha phahameng haholo, ka phetha tshebetso ya workpiece e rarahaneng, 'me e ka ikamahanya le maemo a fetohang ea workpiece. Sistimi ea laser e ka sebelisa lense e cheselitsoeng, lense e sehiloeng, lense e cheselitsoeng e sikiloeng kapa esita le lesela la laser, le kopantsoeng ka matla a khoheli e le hore lilense tse fapaneng li ka fetoha kapele lipakeng tsa tse ling.

Sistimi ea welding laser ea roboto e sebelisoa haholo tlhahisong ea likoloi, metjhini ea boenjiniere, indasteri ea lisebelisoa tsa elektroniki, sebaka sa sefofane, kaho ea masepala le likarolo tse ling. Basebelisi ba khetha ts'ebetso ho latela likarolo tsa bona tsa mosebetsi ha ba e sebelisa.

Likarolo tsa sistimi ea welding ea laser:

1. Ho nepahala ha tjheseletsa ho phahameng.Sebaka sa laser beam sa mochini oa welding oa roboto se nyane, sebaka se amehileng ke mocheso se nyane mosebetsing oa ho tjheseletsa, bakeng sa li-welds tse fapaneng, beam ea laser e ka netefatsa boleng ba weld, sesebelisoa sa ho sebetsa ha se bonolo ho hlahisa deformation, mapetsong le liphoso tse ling tsa welding, letamo la welding la laser le ka hloekisa tšepe ea weld, thepa ea mochini oa weld e lekana kapa e betere ho feta tšepe. Sistimi ea pono e ka hlomelloa ho hlokomela boemo bo nepahetseng pele ho tjheseletsa.

2. Ntlafatsa ts'ebetso ea welding.A robot laser tjheseletsa mochini ka finyella tlhahiso e sa sitisoe ke letho ka mor'a ho qala, haeba mosebedisi hlokomela laser tjheseletsa tlhahiso mola, ho akarelletsa le workpiece loading le laolla, palletizing, ho tšoara le liketso tse ling, ka nka sebaka sa 3 ho 4 ho hanyetsa tjheseletsa liroboto, haeba tšebeliso e feletseng ea thekenoloji tjheseletsa laser, ka hlokomela tlhahiso e bohlale ea mola kaofela tlhahiso, ntlafatsa tjheseletsa bokgoni.

3. Ho feto-fetoha ho matla le ho atolosa,e ka jara mefuta e fapaneng ea liroboto ho latela litlhoko, ho fihlela litlhoko tsa ho nepahala le mojaro o fapaneng. Ha ho na tlhokahalo holim'a thepa ea workpiece, e ka chesetsoa lisebelisoa tse fapaneng, tse kang aluminium, tšepe ea carbon, tšepe e sa hloekang, joalo-joalo.

4. E loketse bakeng sa ho cheselletsa poleiti e tšesaane, laser tjheseletsa mochine ke ho qhibiliha tjheseletsa thepa ka laser, empa laser ke poleiti e khutsoanyane ka botebo tjheseletsa. Ha se hore laser deep welding ha e khonehe, ke hore e bitsa chelete e ngata haholo. Argon arc welding e na le litšenyehelo tse ngata ha ho hlokahala ho kenella ka botebo ho tjheseletsa thepa e teteaneng haholo.

Shanghai Jiesheng e tsepamisitse maikutlo ho sistimi ea welding ea liroboto, e na le boiphihlelo bo bongata, ho fa bareki litharollo tse ikhethileng.

Nako ea poso: Mar-21-2023